September 2016

Will Hall finishes the season on a high

25th September 2016: Recent Geartronics convert Will Hall took an excellent 3rd & 2nd place in the final two run-offs of the British Hillclimb Championship at Loton Park, setting a new personal best time of 45.74 along the way. The second and final run-off of the year was probably the closest ever seen on the British hills, in fact it couldn't get any closer - Will set a time of 46.45, pipping Scott Moran by 1/100 of a second, only to be beaten himself by 1/100 by fellow Geartronics customer Wallace Menzies!

25th September 2016: Recent Geartronics convert Will Hall took an excellent 3rd & 2nd place in the final two run-offs of the British Hillclimb Championship at Loton Park, setting a new personal best time of 45.74 along the way. The second and final run-off of the year was probably the closest ever seen on the British hills, in fact it couldn't get any closer - Will set a time of 46.45, pipping Scott Moran by 1/100 of a second, only to be beaten himself by 1/100 by fellow Geartronics customer Wallace Menzies!

Will, driving a Force WH single-seater, had decided to take a different approach this season by fitting a 2-litre 4-cylinder AER turbo engine. Historically, turbocharged engines have not been particularly successful in British hillclimbing due mainly to the tight & twisty nature of some of the courses and the difficulty in keeping the engine 'on boost'. However, modern turbo boost control has put the engines back on a par with the much larger naturally aspirated V8's that have dominated the sport for so many years, especially given their much lower weight. Unfortunately, Will's season didn't get off to a good start due to ongoing gear shift issues that usually resulted in the car being brought back to the paddock on the end of a rope! After repeated and unsuccessful attempts by the incumbent supplier to resolve the issues, Geartronics were eventually brought in to make the car reliable.

The transmission is the well-proven Hewland TMT with built-in pneumatic actuators, so we were 100% confident that the gearbox was not the source of the problems. Nor was the gear shift hardware as this was a combination of ours and Shiftec components. The solution to the problem was to use the existing MoTeC M1 ECU, but using our own internal shift strategies rather than MoTeC's own 'GPRP' software package. Not that there's anything fundamentally wrong with GPRP when setup by someone who knows what they're doing, but we believe that our shift strategies are better developed for the specific requirements of a high boost forced induction engine. Of course, having the advanced software is one thing, but our vast experience in gearbox control setup was also essential in arriving at a reliable solution. So, with the software in place, we headed off for a quick test at Curbrough sprint course along with Lee Penn of LAP Engineering. Lee had been brought in by the customer to re-map the engine in order to give the necessary throttle blip response so that we actually stood a fighting chance of optimising the downshifts, which had been the fundamental problem all season. During the initial mapping session on the engine dyno it quickly became apparent that the standard GPRP software package was unable to properly control a turbo engine on individual throttles. It was therefore necessary for Nathan Sanders of Race Data Systems to write some additional code to allow a throttle compensation to the existing RPM/boost fuel calibration. Anyway, with the mapping completed, we now had an engine that produced a smoother power delivery and considerably better throttle response than the old setup, and as a bonus it also used less fuel and generated less noise as a result! After a few runs, we had the car shifting up and down the box better than it had done all season, and Will was now confident that he might have a winning car on his hands. The summer holidays intervened in the testing programme so a second test was scheduled upon our return. After a further couple of hours we were all happy that the shifting was smooth & reliable. From this point onwards, albeit late in the season, the car never missed a shift, and it's now in a position to challenge for the championship next year.

If you're interested in paddleshift for you car, be it hillclimb, rally, race or whatever, then please contact either ourselves or our MoTeC partners Race Data Systems.

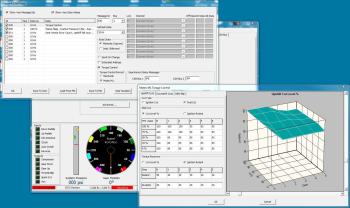

GCU-3 software update

Work continues on software development for our professional GCU-3 unit. The latest version sees siginificant improvements to the data-logging download speed, now 2.5x faster, as well as further enhancements to the CANbus communication options. We're confident that our standalone GCU-3 is one of the most powerful, flexible and user-friendly gearbox control units on the market.

Work continues on software development for our professional GCU-3 unit. The latest version sees siginificant improvements to the data-logging download speed, now 2.5x faster, as well as further enhancements to the CANbus communication options. We're confident that our standalone GCU-3 is one of the most powerful, flexible and user-friendly gearbox control units on the market.

Please note that this software is only compatible with our 'Pro' GCU-3 unit, and calibration options are only visible when either connected to the GCU or if you have a valid configuration file. For users with the original GCU (identified by the 25-way AMP connector) please contact us for the latest software version.

April 2016

Martin Hodgson takes overall victory

17th April 2016: Long-time Geartronics customer Martin Hodgson has taken his Escort MKII to outright victory on the JC Motor Services rally at the Anglesey circuit.

17th April 2016: Long-time Geartronics customer Martin Hodgson has taken his Escort MKII to outright victory on the JC Motor Services rally at the Anglesey circuit.

Powered by a new Smith & Jones 2.5 litre engine, after 10 stages, Martin took a comfortable 32s victory from second-placed Brandon Smith in a Darrian T9.

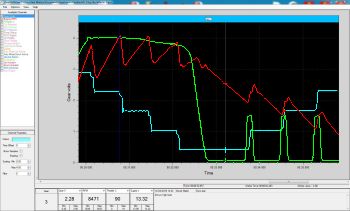

Just before the rally, Martin took the car for a dyno session at Sheffield Rolling Road to optimise the ECU calibration with engine builder Will Jones. As we're only a couple of miles up the road, we attended the session to check the setup of the gearbox control unit and configure the gear cut settings in his new DTA ECU. Although Martin's car uses our original GCU-1, we piggybacked a GCU-3 into the wiring loom so as to use it as a data logging device. Click on the screenshot below to see just how smoothly our system is shifting the Tractive RD906 gearbox!

Just before the rally, Martin took the car for a dyno session at Sheffield Rolling Road to optimise the ECU calibration with engine builder Will Jones. As we're only a couple of miles up the road, we attended the session to check the setup of the gearbox control unit and configure the gear cut settings in his new DTA ECU. Although Martin's car uses our original GCU-1, we piggybacked a GCU-3 into the wiring loom so as to use it as a data logging device. Click on the screenshot below to see just how smoothly our system is shifting the Tractive RD906 gearbox!

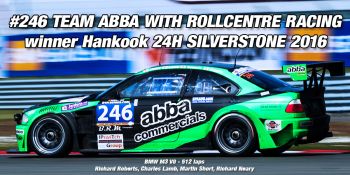

Rollcentre Racing take outright victory at Silverstone 24hour

The first weekend in April saw the Hankook 24hr Series visit the famous Silverstone circuit for the second round of the hotly contested international endurance championship. In a repeat performance of the 2012 race, for the car at least, the BMW M3 GTR of Rollcentre Racing with abba Commercials took outright victory, completing a total of 512 laps in 24 hours.

After a spate of driveshaft failures during Friday practice & qualifying, not many people would have given the team much of a chance of finishing, let alone winning the race. The car actually failed to set a qualifying time and would be destined to start from the back of the grid. Not that grid position really matters for a 24 hour endurance race, but being a bit closer to the sharp end would have undoubtedly given the team a bit more confidence going into the race. The driveshaft failures were actually attributable to a gearbox issue which was causing inconsistent and aggressive shifting. After a gearbox replacement late on Friday afternoon, Geartronics director Neil Wallace arrived at the circuit to check the setup and correct a small wiring problem. The car was finished just in time for night qualifying, and all drivers then reported that the shifting was back to normal. Data logging was examined after each driver change, and the gearbox was given a clean bill of health for the race.

Richard Neary was at the wheel for the start of the race, and he quickly set about carving through the field to put the BMW into 6th position overall by the end of the first hour. By midnight, the team were up to 4th place, and 3rd by the halfway mark. At 16 hours, the team had settled into a comfortable 2nd place, but it looked unlikely that they would be able to overhaul the leading Seat Leon of Team Bleekemolen. However, as is often the case with endurance racing, a bit of luck is needed to finish on the top step of the podium, and that luck came in the form of an engine failure for the leading car in the 19th hour. It was then just a matter of the team holding their nerve to bring the car home. Darren Cox (AKA Richard Roberts) completed the final trouble-free stint to bring the car over the line with a comfortable 3 lap advantage over the second placed Red Camel-Jordans Seat Leon.

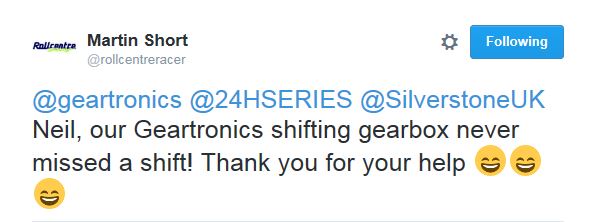

After the race, team owner Martin Short Tweeted that the Geartronics paddleshift system never missed a shift for the entire race.

A bit of a milestone!

It doesn't seem like 5 minutes ago since the first protortpe was being tested on a smokey old Ford Sierra, but this month we've produced the 1000th first-generation gearbox control unit. Over the years, there have been 4 hardware iterations and 47 software updates to bring the unit to this point. GCU-1, as it's known, will continue to be produced alongside our 'professional' GCU-3 version, and we're already looking forward to the next 1000...

It doesn't seem like 5 minutes ago since the first protortpe was being tested on a smokey old Ford Sierra, but this month we've produced the 1000th first-generation gearbox control unit. Over the years, there have been 4 hardware iterations and 47 software updates to bring the unit to this point. GCU-1, as it's known, will continue to be produced alongside our 'professional' GCU-3 version, and we're already looking forward to the next 1000...

March 2016

Sadev hydraulic paddleshift system

This month we've been busy writing software to control the Sadev hydraulic paddleshift system. A hydraulic system is similar in operation to our pneumatic system, but the shift pressure is obviously much higher (60bar as opposed to 8bar). One of the differences with the Sadev hydraulic system is that it has 2 pressure sensors: a high-pressure sensor for the accumulator pressure, and a low-pressure sensor for the oil reservoir. The latest software has options for either pneumatic or hydraulic operation, with the appropriate sensor scaling. Version 3.28 of our GCU-3 software untilises a 'spare' analogue input channel to read the reservoir pressure sensor. If the system detects the pressure to be less than 1.1bar we transmit the appropriate CAN message to the dashboard to warn the driver of possibly low hydraulic oil level.

This month we've been busy writing software to control the Sadev hydraulic paddleshift system. A hydraulic system is similar in operation to our pneumatic system, but the shift pressure is obviously much higher (60bar as opposed to 8bar). One of the differences with the Sadev hydraulic system is that it has 2 pressure sensors: a high-pressure sensor for the accumulator pressure, and a low-pressure sensor for the oil reservoir. The latest software has options for either pneumatic or hydraulic operation, with the appropriate sensor scaling. Version 3.28 of our GCU-3 software untilises a 'spare' analogue input channel to read the reservoir pressure sensor. If the system detects the pressure to be less than 1.1bar we transmit the appropriate CAN message to the dashboard to warn the driver of possibly low hydraulic oil level.

One of the drawbacks of a hydraulic system is the force required to push the actuator back to the centre position because of the need to displace the fluid from the actuator. However, this problem is easily overcome by our unique 'active return' strategy which has proven extremely valuable, even on a pneumatic system, when working with gearboxes that only have a weak lever return spring.

Now that our GCU-3 control unit has been updated to control the hydraulic system, Sadev users are no longer tied to the Cosworth/Pectel GCU-L which is notoriously difficult to setup.

Click here to see a short video we posted to our Twitter feed, showing the hydraulic unit being bench tested. The video demonstrates our stacked downshift facility and the speed potential of the hydraulic system. Of course, in practice it's not possible to shift this quickly, so we don't make any advertising claims that it's possible to shift in a real-world application in as little as 15mS or make five downshifts in less than half a second, we'll leave that sort of bullshit to the others!

January 2016

New platform for Geartronics shift control.

Working in conjunction with highly regarded MoTeC specialists Race Data Systems, we have spent the past few months writing our renowned gearbox control strategies into the MoTeC M1 firmware. Building on top of the 'GPR' package, the MoTeC developer software, 'Build', allows coders to write their own control strategies for whatever application they see fit. Gearbox control is naturally one of the most obvious additions to the base package, and we are now in a position to offer our complete hardware, software and support solution for teams wishing to integrate all functions into a single ECU.

Having fully bench tested the new software on the Geartronics test rig, and subsequently on a real car on a chassis dyno, we then conducted the first successful track test just before Christmas at an unseasonably warm Silverstone. Using a BMW E46 with a Drenth DG400 gearbox, we completed in excess of 30 trouble-free laps around the GP circuit. As expected, the test was little more than a tuning excercise as we were confident of the code working as it should, given that the tried & tested strategies have been used in our standalone GCU's for many years.

Having fully bench tested the new software on the Geartronics test rig, and subsequently on a real car on a chassis dyno, we then conducted the first successful track test just before Christmas at an unseasonably warm Silverstone. Using a BMW E46 with a Drenth DG400 gearbox, we completed in excess of 30 trouble-free laps around the GP circuit. As expected, the test was little more than a tuning excercise as we were confident of the code working as it should, given that the tried & tested strategies have been used in our standalone GCU's for many years.

For further information, please contact either ourselves, or Nathan Sanders at Race Data Systems

December 2015

Track support news

One of the final track tests of 2015 saw Geartronics director Neil Wallace visit the Magny Cours circuit in central France to setup the paddleshift system on a Porsche 997 Cup car owned by Luc Marichez. Unlike most ex-Cup 997's, this car was fitted with the PARR/Quaife transmission in place of the original Porsch/Holinger unit. However, the car was still fitted with the factory Bosch engine management system and MoTeC ADL dashboard.

One of the final track tests of 2015 saw Geartronics director Neil Wallace visit the Magny Cours circuit in central France to setup the paddleshift system on a Porsche 997 Cup car owned by Luc Marichez. Unlike most ex-Cup 997's, this car was fitted with the PARR/Quaife transmission in place of the original Porsch/Holinger unit. However, the car was still fitted with the factory Bosch engine management system and MoTeC ADL dashboard.

The locked Bosch MS3 Sport ECU fitted to these cars presents us with significant problems because we can't re-configure the gear cut or even the gear position voltages. This means that we have to fit a specially calibrated hall-effect sensor to mimic the original Porsche supplied sensor, and we have to use a solid-state relay to cut the ignition coils during the downshift sequence. Other systems don't bother with the downshift cuts, and simply reply on the throttle blip to control the engine speed on downshifts. However, this is a big compromise because it usually means that you have to use less than the optimal amount of throttle blip. Anyway, we devised a method to apply an engine cut for both up and down shifts to maximise the performance of the system. This necessitated the use of our 'professional' GCU3 as this has the ability to control up and down cuts separately. It also allows us to read various parameters from the CAN bus rather than splicing into numerous separate signals.

By the end of the test, the car's owner was delighted with the results. Interestingly, we were able to do a back-to-back test alongside the latest 991 Cup car with factory paddleshift. With both professional and amateur drivers at the wheel of the two cars, there was no discernible difference in the shift quality between the two systems.